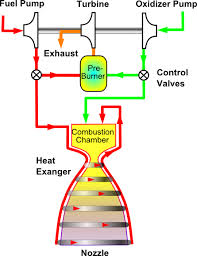

A liquid-propellant rocket or liquid rocket uses a rocket engine burning liquid propellants. (Alternate approaches use gaseous or solid propellants.) Liquids are desirable propellants because they have reasonably high density and their combustion products have high specific impulse (Isp). This allows the volume of the propellant tanks to be relatively low.

Liquid rockets can be monopropellant rockets using a single type of propellant, or bipropellant rockets using two types of propellant. Tripropellant rockets using three types of propellant are rare. Liquid oxidizer propellants are also used in hybrid rockets, with some of the advantages of a solid rocket. Bipropellant liquid rockets use a liquid fuel such as liquid hydrogen or RP-1, and a liquid oxidizer such as liquid oxygen. The engine may be a cryogenic rocket engine, where the fuel and oxidizer, such as hydrogen and oxygen, are gases which have been liquefied at very low temperatures.

Most designs of liquid rocket engines are throttleable for variable thrust operation. Some allow control of the propellant mixture ratio (ratio at which oxidizer and fuel are mixed). Some can be shut down and, with a suitable ignition system or self-igniting propellant, restarted.

Advantages and disadvantages

Advantages

- A liquid rocket engine can be tested prior to use, whereas for a solid rocket motor a rigorous quality management must be applied during manufacturing to ensure high reliability.

- Liquid systems enable higher specific impulse than solids and hybrid rocket motors and can provide very high tankage efficiency.

- A liquid rocket engine can also usually be reused for several flights, as in the Space Shuttle and Falcon 9 series rockets, although reuse of solid rocket motors was also effectively demonstrated during the Shuttle program.

- The flow of propellant into the combustion chamber can be throttled, which allows for control over the magnitude of the thrust throughout the flight. This enables real-time error correction during the flight along with efficiency gains.

- Shutdown and restart capabilities allow for multiple burn cycles throughout a flight.

- In the case of an emergency, liquid propelled rockets can be shutdown in a controlled manner, which provides an extra level of safety and mission abort capability.

disadvantages

- Because the propellant is a very large proportion of the mass of the vehicle, the center of mass shifts significantly rearward as the propellant is used; one will typically lose control of the vehicle if its center mass gets too close to the center of drag/pressure.

- When operated within an atmosphere, pressurization of the typically very thin-walled propellant tanks must guarantee positive gauge pressure at all times to avoid catastrophic collapse of the tank.

- Liquid propellants are subject to slosh, which has frequently led to loss of control of the vehicle. This can be controlled with slosh baffles in the tanks as well as judicious control laws in the guidance system.

- They can suffer from pogo oscillation where the rocket suffers from uncommanded cycles of acceleration.

- Liquid propellants often need ullage motors in zero-gravity or during staging to avoid sucking gas into engines at start up. They are also subject to vortexing within the tank, particularly towards the end of the burn, which can also result in gas being sucked into the engine or pump.

most liquid rocket are launched by companys as they are much more complicated than solid rocket motors

But there are a few exeptions a few people have managed to build liquid rockets as amatures